Filters

-

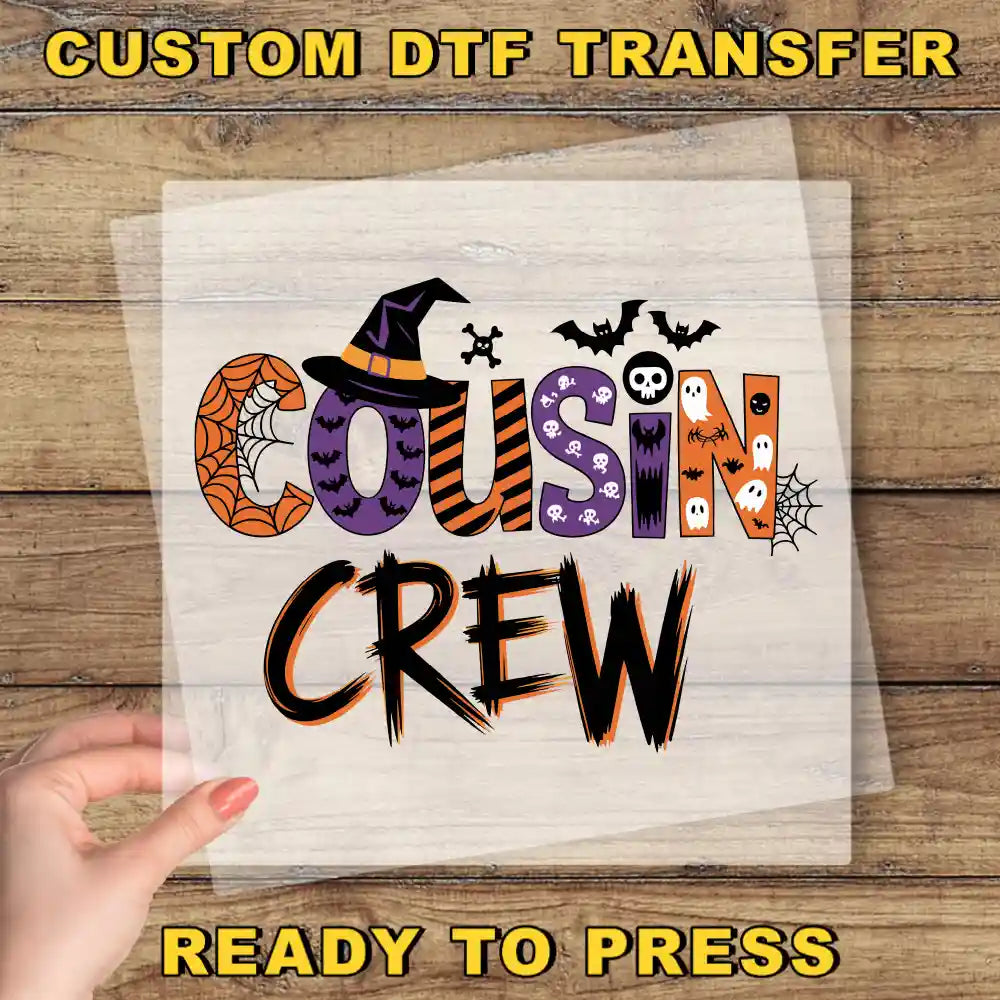

Halloween Cousin Crew Ready To Press Design, Halloween Party Matching DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Coquette Bow Halloween Ready To Press Design, Spooky Season DTF Transfer

Sale price From $1.80 Regular price$3.60 -

Spooky Season Ready To Press Design, Cute Halloween Ghost DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Salt Water And Sun Shine Ready To Press Design, Retro Summer Beach DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Beach Trip 2025 Ready To Press Design, Family Vacation DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Book Girl Summer Ready To Press Design, Bookish Beach Holiday DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Iridescent Ghost Ready To Press Design, Halloween Coquette Ghost DTF Transfer

Sale price From $1.80 Regular price$3.60 -

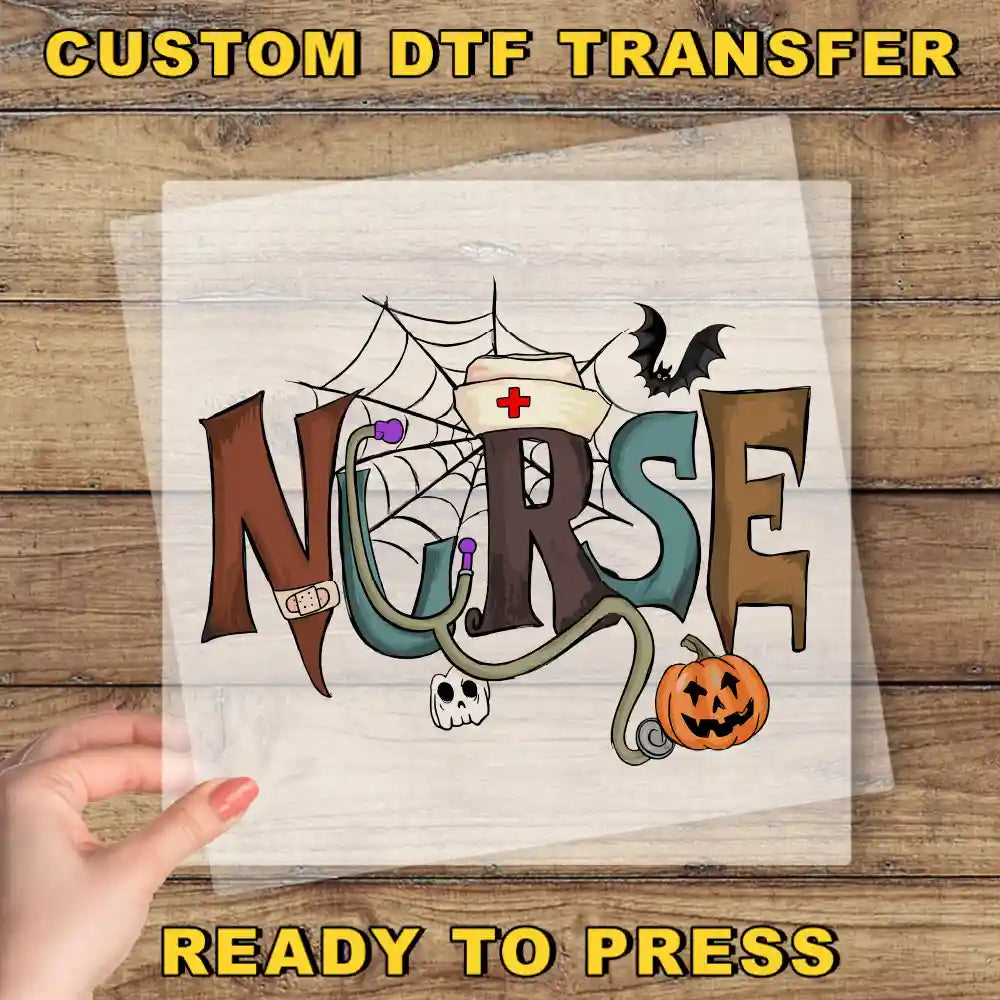

Nurse Halloween Ready To Press Design, Spooky Health Professional DTF Transfer

Sale price From $1.80 Regular price$2.00 -

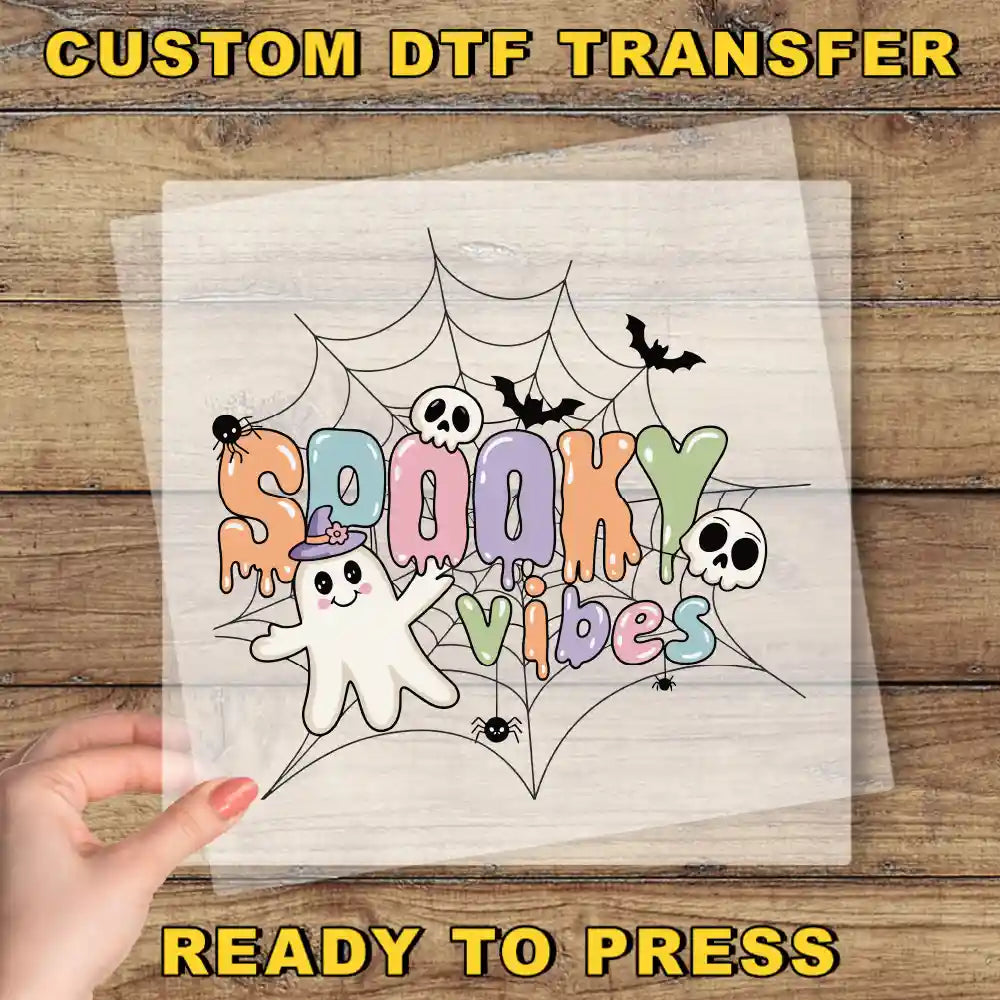

Spooky Vibes Ready To Press Design, Halloween Ghost DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Just A Boy Who Loves Dirt Ready To Press Design, Construction Excavator DTF Transfer

Sale price From $1.80 Regular price$3.60 -

Summer Break Cat Ready To Press Design, Funny Teacher DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Summer Beach Ready To Press Design, Hawaii Vacation DTF Transfer

Sale price From $1.80 Regular price$3.60 -

Ghost Cows Ready To Press Design, Halloween Cow DTF Transfer

Sale price From $1.80 Regular price$2.00 -

4th Of July Hot Dog Ready To Press Design, Independence Day DTF Transfer

Sale price From $1.80 Regular price$2.00 -

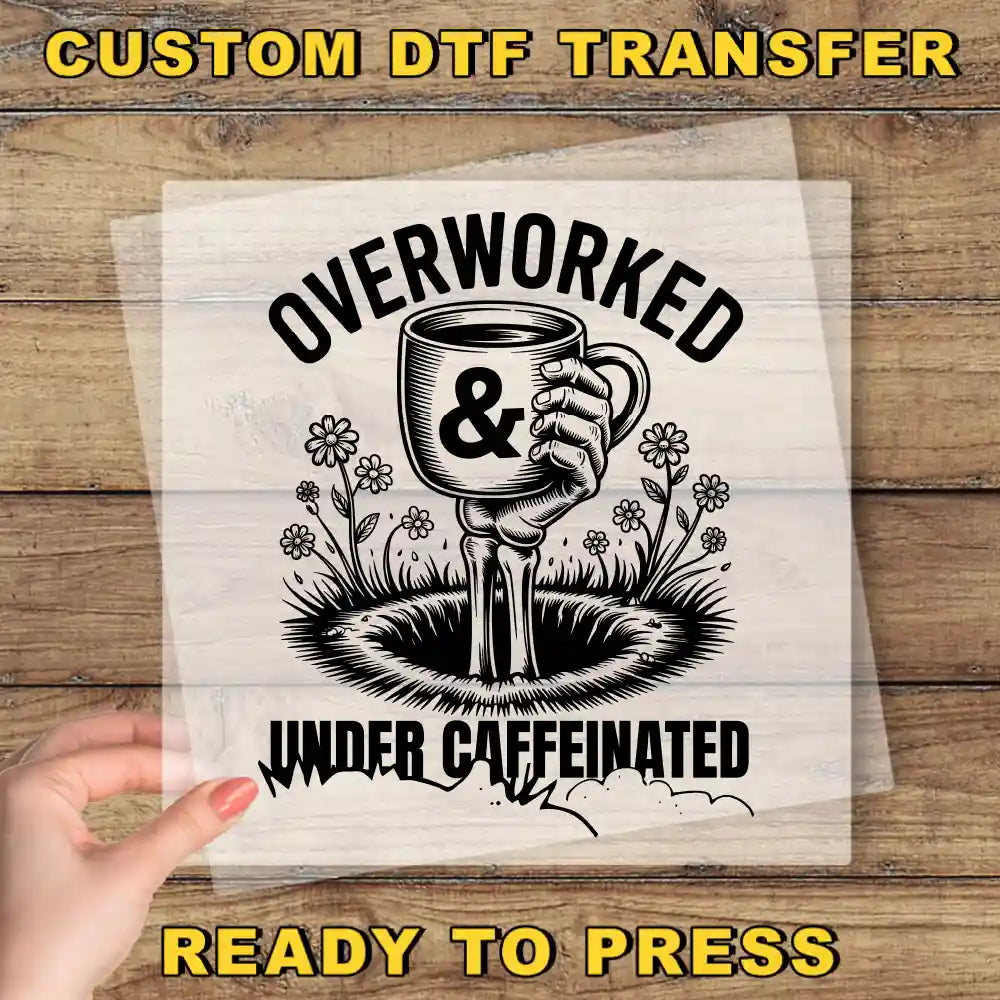

Overworked Under Caffeinated Ready To Press Design, Coffee Lover DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Always Be Kind Ready To Press Design, Kindness DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Grow Freely Bloom Wildly Ready To Press Design, Inspirational DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Pumpkin Spice Era Ready To Press Design, Squirrel Halloween DTF Transfer

Sale price From $1.80 Regular price$2.00 -

This Is My Halloween Costume Ready To Press Design, Spooky Season DTF Transfer

Sale price From $1.80 Regular price$2.00 -

I Myself Am Strange And Unusual Ready To Press Design, Halloween DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Trick Or Treat Ready To Press Design, Cute Ghost Dog DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Emotional Baggage Ready To Press Design, Funny Quote DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Summer Vibes Halloween Ready To Press Design, Summerween DTF Transfer

Sale price From $1.80 Regular price$2.00 -

Custom Painter Ready To Press Design, Personalized Artist DTF Transfer

Sale price From $1.80 Regular price$3.60

Showing 24 of 144

Load moreDTF Transfers Ready to Press

DTF transfers ready to press is a printing technology that saves time and labor with practical and durable printing solutions. The method attracts attention, especially in the textile industry with its customized printing solutions, and meets individual and corporate needs.

DTF enables professional results by transferring the artwork to the fabric in high resolution and vibrant colors. Since it is a printing technology compatible with different types of fabrics, its area of use is quite diverse. It also offers quality designs suitable for every project thanks to its high washing resistance and color saturation.

What Does “DTF Transfers Ready to Press” Mean?

DTF transfers ready to press are printing materials that enable the transfer of the pre-prepared design film to the fabric with the help of a heat press. In this printing method, the design is printed on a special film, then coated with adhesive powder and dried.

This process is called curing and guarantees a strong and effective adhesion of the powder to the surface. Ready press indicates that the print is ready to be applied and allows the process to take place quickly.

DTF Transfers: Pre-Cut & Ready

DTF transfers are ready to apply pre-cut. Accordingly, they do not require materials such as scissors and cutting tools. The excess around the transfers is cut off and only the design part is left. As well as this, direct to film transfers are pre-cut, allowing for error-free results.

To print DTF transfers, a special equipment called a heat press is needed. The heat press, which works with a combination of an upper and lower press plate, ensures that the transfer is applied to the fabric with equal pressure. In addition, since it is a device operating at high temperatures, it allows the design to be transferred permanently and clearly. Often applied to garments, the heat press adapts to different types of fabrics, offering a wide range of production flexibility.

DTF transfers ready to press can also be used with household irons. There are points to be considered when applying this method, which offers effective results in simple projects. For DTF transfers, the iron must be preheated to 300°F and the steam function must be disabled. During the printing phase, it is important to apply the design film consistently for approximately 20 to 30 seconds. The iron is an effective method for simple designs, while a heat press is preferable for professional and high-volume projects.

Best Temp & Time for DTF Press

Temperature and time settings in the printing process are different depending on the material used. At this point, these factors are of great importance to prevent damage to the print. For cotton fabrics, a temperature of 320-350°F (160-180°C) is ideal and should be applied at a medium to heavy level for 10-15 seconds. For synthetic & polyester fabrics, it is recommended to press at 280-300°F (140-150°C) with medium pressure for 10-15 seconds.

DTF transfers ready to press 50/50 blends should be applied at 320-350°F (160-180°C) for a minimum of 10 and a maximum of 15 seconds. The temperature and time settings are also related to the fabric thickness. At this point, it is appropriate to increase the degree of pressing on materials such as denim and canvas. For delicate fabrics such as silk, poplin, and tulle, it is recommended to keep the temperature and time values low.

Using Home Press for Ready-to-Press DTF

It is possible to use a home heat press for DTF transfers ready to press. The equipment has lower pressure and temperature control than a professional heat press. Therefore, you should consider the applied fabric surface and design requirements. It is essential to customize the temperature and press settings depending on these factors.

What Materials Can I Apply Ready to Press DTF Transfers Onto?

DTF transfers ready to press can be applied mostly on fabrics made of cotton, polyester, or a blend of the two. They also work well with materials such as canvas, leather, and nylon. The most common materials on which Custom DTF transfers ready to press are as follows:

Cotton

Cotton, which stands out with its soft texture, is a fabric that allows DTF transfers to hold efficiently. In addition, thanks to its breathable feature, it preserves the print quality for a long time and offers a comfortable use.

Since cotton is a fabric containing natural fibers, it binds ink and adhesive together. Thanks to these properties, cotton t-shirts, sweatshirts, and cardigans are especially preferred for DTF processes.

Polyester

Polyester is one of the fabrics where DTF printing gives the best results. This is because the ink adheres strongly to the fabric thanks to the light and smooth structure of the material in question. In addition, polyester fabrics increase the aesthetic quality of the print as they make the colors look vibrant and bright. The material, which stands out with its moisture-wicking properties, is mostly preferred in sportswear and equipment.

Fabric Blends

Fabrics with a blend of natural and synthetic fibers offer a suitable alternative for DTF transfers ready to press. In particular, blends of 50% cotton and 50% polyester combine the advantages of both materials to improve print quality.

The fabrics strike a balance between softness and flexibility, allowing for durable results in design projects. In addition, viscose, cotton, and polyester blends ensure that the print looks smooth. However, it increases the vibrancy of colors and improves the aesthetic quality of products.

Nylon

Nylon, which stands out with its smooth surface and non-porous structure, is ideal for DTF transfers ready to press applications. However, since it is a heat-sensitive material, it is very important to consider the temperature setting and application time.

Nylon backpacks and sportswear products are generally preferred in DTF printing projects. As it is a durable material, it shows long-lasting performance even in items that require frequent use.

Leather

Leather is a material used in DTF printing projects thanks to its flexible and durable structure. Both natural and artificial forms are suitable for the process.

Denim

Denim, which has a bumpy fabric texture, gives successful results in DTF transfers ready to press applications. In addition, as it is a type of fabric that offers timeless style, it allows different designs to be applied aesthetically.

Jean pants and denim jackets emphasize elegance in personal DTF projects. In addition, the ink integration process proceeds in harmony with the durable structure of the fabric.

Canvas

DTF transfers ready to press adds an artistic touch to canvas products and clearly emphasizes the details of the prints. Especially on tote bags, murals, and decorative textiles, the details shine brightly. For example, Disney DTF transfers ready to press applied on these items clearly reveal the colors of the beloved characters.

The design, enriched with eye-catching color transitions, shadows, and details, delivers a product that is a work of art. The harmonious ink integration of DTF printing allows the colors to become vibrant and lasting.

Vibrant & Durable DTF Colors

Colors vibrant and lasting designs are achieved after pressing. Thanks to DTF transfer working with special ink and printers, the designs become suitable for long-term use. For example, Christmas DTF transfers ready to press keep their brightness with various colors such as red, green, and white. Produced with high-quality printing technology, the product is resistant to washing and external factors for a long time.

Storing Ready to Press DTF Transfers Properly

Ready to print DTF transfers should be stored in an extremely cool environment away from sunlight. This is because environmental factors such as extreme temperature, humidity, and dust can cause deterioration of the printing products. At this point, the conditions for proper storage of DTF transfers are as follows:

- You can store DTF transfers at room temperature and in a dry environment. Excessively hot environments can cause the products to stick, while cold areas adversely affect their structure.

- Sun rays affecting DTF transfers cause peeling and deterioration on the surface. Therefore, they should be stored in a sheltered place away from sunlight.

- Dust adheres to the transfer surface and causes some difficulties during application. In particular, it reduces the level of adhesion and prevents the desired results from being obtained.

DTF transfers ready to press can be used within 3 to 12 months when stored properly. If there is no suitable storage environment, it is recommended to use the products within 30 days.

Do You Offer Bulk Pricing for Ready to Press Transfers?

We offer bulk pricing on large-volume DTF transfer orders. With our budget-friendly solutions, you can manage your business's design projects economically. Custom Print House offers DTF transfers ready to press wholesale and special pricing opportunities.

You can contact us to make your printing projects more profitable and advantageous. Wholesale orders offer cheap DTF transfers ready to press purchasing opportunities and significantly reduce costs.

Customizing DTF Ready-to-Press Transfers

You can create custom designs for your own brand or individual design projects and get them ready to press. Custom Print House, which offers the best DTF transfers ready to press solutions, prints the images you dream of with the most vivid colors and details.